|

| |

Optical Image Correlating Velocimeter for

metallurgical plants

Optical Image Correlating Velocimeter (ICV) was developed to measure

speed and length of product in metallurgical process. The ICV represents alternative

solution to laser doppler based instruments achieving similar accuracy on good quality

surfaces and superior accuracy on rough and poor quality surfaces. For detailed

description of principle of operation refer to paper [1]. The

production model of the ICV is shown in Fig.1.

|

Fig.1.Image Correlating Velocimeter |

Basic Characteristic of the ICV

No contact measurement of speed , length, and distance to the product

Small size and weight

Wide range of stand-off distance

Mesure distance to object

Works well from very slow to medium range of product velocity

Instantaneous measurement of speed and displacement of the product

Wide operating temperature range

Quick and easy installation and service

Speed and length measurement of slab in

continuous casting process using ICV

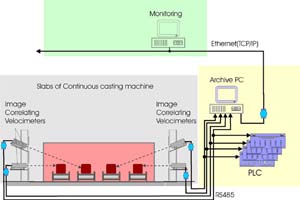

The ICV has been installed on quad continuous caster machine, connected

to MNLZ process control system, and operated flawlessly over 9 month period. Figure 2

shows installation diagram and four ICVs monitoring quad caster machine. The point of

installation was close to the slab cutting machine. Figure 3 shows photograph of two ICVs

monitoring first and second slab on the quad caster. ICV at the bottom is pointed at the

first slab, which is 1800mm away, while upper instrument monitors the second slab 3700 mm

away. At this distance both ICVs operated without need for cooling. All four ICVs were

connected to process control and monitor computer, which processed and recorded data. Data

from the ICV can be also used to control operation of slab cutting machine. Important

feature of ICV is instantaneous reading of slab velocity and possibility to detect fast

and sudden changes in slab speed caused by instability in the crystallizer. Test results

of pilot installation and operation of the ICV were published in papers[3] and [4].

|

Fig.2. Installation diagram of four ICVs

on quad casting machine |

|

|

Fig3. ICVs monitoring

slab 1 and 2 |

Fig.4. Computer rack |

Definition of measurements and data format

Instantaneous velocity: slab movement speed in mm/sec

Length: slab length in mm measured from the moment of entering the

ICV field of view or from the moment of starting new measurement

Distance: distance in mm from the reference point on the ICV to the

slab surface

Technical specification of process control system MNLZ for

continuous caster machine

- Slab temperature: 450...1100°С

- Slab velocity: -5...+5 m/min

- Velocity measurement accuracy: 1 %

- Length measurement accuracy: 0.15 %

- Stand-off distance:1600...4000 mm

- Depth of field: 600 mm

- Distance measurement accuracy: 0.2 %

- Output data rate: 8…16 Hz

- Digital data interface : RS485

- Operating ambient temperature range: -10...+60°С

- Enclosure environmental rating : IP-54

- External cooling: N/A

- Supply voltage: 220 VAC or 24 VDC

ICV controlling billet cutting machine

Figure 5 show ICV installed 2100 mm from the billet surface and

controlling cutting machine.

|

Fig.5 ICV controlling billet cutting

machine |

Technical specification of billet cutting system

- Billet temperature range: 450...1100°С

- Billet velocity range: -4...+4 m/sec

- Velocity measurement accuracy: 1 %

- Length measurement accuracy: 0.15 %

- Stand-off distance: 2000...2600 mm

- Depth of field: 600 mm

- Output data rate: 100 Hz

- Digital data output: RS-485

Installation requirements and operational limits:

For accurate operation measured object must fill ICV’s field of view,

which at 2 m distance is 20 mm high and 250 mm wide. At 4 m distance field of view is 40

mm high and 500 mm wide.

ICV operates properly over product temperature range of 1100°C to

450°C. Measuring to cooler products requires additional illumination. Two 100W bulbs

placed at 2 m to 2.5 m distance from the product surface provide sufficient illumination.

Bibliography

(All articles in russian)

- Аникин А.В., Иерусалимов И.П., Суковатин И.В.

// Современные технологии автоматизации. - 2001. - №4.

- С.22-26 (not represent at this site)

- Иерусалимов И.П., Федоров Л.К., Черкасов

В.Б., Шеховцов Е.В. // Сталь. 2002. №7. С.25-27 (not represent at this

site)

- Иерусалимов И.П., Суковатин

И.В. Исследование динамики продвижения слитка

МНЛЗ при разливке // Сталь. - 2003. - №4. - С.26.

- Аникин А.В., Иерусалимов И.П.,

Суковатин И.В. Система контроля перемещения

слитка// Современные технологии автоматизации. -

2004. - №1. - С.18-22.

- Аникин А.В., Иерусалимов И.П.

Система контроля длины блюмов при порезке

слитка// Сталь. - 2004. - №7. - С.47.

- Аникин А.В., Иерусалимов И.П. // Сталь. 2004. №9.

С.28-29 (not represent at this site)

- Иерусалимов И.П., Карфидов Ю.Н., Литвинов А.М.

Контроль порезки слитков на блюминге //

Современные технологии автоматизации. - 2007. - №1. -

С.18 (in the

magasine site)

- Иерусалимов И.П., Цыпин В.Н.

Оптические стереокамеры для металлургии //

Датчики и системы. - 2010. - №10. - С.35

Contact:

Firm:

Лаборатория оптоэлектронной техники

mailbox: Russia, 622025, Нижний Тагил, Металлургов, 1, а/я 1

phone:

(3435)490087

e-mail:

info@loet.ru

|